2024 Hazardous Waste Environmental Pollution Prevention and Control Responsibility System

Release time:

2022-07-23

Shandong Kafu Lego Polymer Materials Co., Ltd.

Hazardous Waste Environmental Pollution Prevention and Control Responsibility System

1. Purpose

In order to implement the national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure the sustainable development of production, this system is specially formulated.

2. Scope of Application

This system applies to the management of hazardous waste within the company.

3. Specific Requirements

3.1. Honestly report the generation of hazardous waste and earnestly implement the hazardous waste information reporting system.

3.2. Implement the responsibility system and assign responsibilities to individuals. Strictly follow relevant regulations and requirements, establish and improve the pollution prevention and control responsibility system, adopt pollution prevention measures, and prevent and reduce the pollution of solid waste to the environment.

3.3. Formulate and improve preventive measures and emergency plans for sudden hazardous waste accidents and report them for the record.

3.4. The transfer of hazardous waste must be notified to the Environmental Protection Bureau in advance. According to national regulations, fill out the hazardous waste transfer slip, and the receiving unit submits an application before the transfer can be carried out after approval.

3.5. Hazardous waste shall never be provided or entrusted to units without business licenses for collection, storage, disposal, or utilization.

3.6. Establish storage facilities and sites that meet standards. The generated hazardous waste shall be stored in bags, legally marked, and managed by a designated person.

Effective from February 2024.

Shandong Kafu Lego Polymer Materials Co., Ltd.

February 28, 2024

Information Disclosure of Hazardous Waste Pollution Prevention and Control Responsibility System

Weifang Fule New Materials Co., Ltd.

| Serial Number |

Hazardous Waste Name |

Hazardous Waste Code |

Hazardous Waste Characteristics |

Source and Generation Process |

Disposal Method |

Person in Charge |

Contact Information |

| 1 |

Waste Heat Transfer Oil |

HW08(900-249-08) |

Toxicity, Flammability |

Generated during heat transfer oil replacement |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 2 |

Waste Activated Carbon |

HW49(900-039-49) |

Toxicity |

Generated during exhaust gas absorption replacement |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 3 |

Waste Cleaning Solution |

HW49(900-047-49) |

Toxicity, Flammability, Reactivity, Corrosivity |

Cleaning of laboratory equipment and instruments |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 4 |

Waste Gear Oil |

HW08(900-217-08) |

Toxicity, Flammability |

Equipment maintenance |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 5 |

Non-conforming product organic resin |

HW13(265-101-13) |

Toxicity |

Non-conforming products generated during production |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 6 |

Organic resin waste |

HW13(265-103-13) |

Toxicity |

Generated during filtration in the production process |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 7 |

Waste Catalyst |

HW50(772-007-50) |

Toxicity |

Generated when replacing the catalyst in the RCO equipment |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

| 8 |

Waste filter cotton and waste packaging materials |

HW49(900-041-49) |

Toxicity, infectivity |

Waste filter cotton and waste packaging materials |

Entrusted to a qualified unit for disposal |

Nie Wenbing |

15163628810 |

Disposal unit for this year: Shandong Chunfan Environmental Technology Co., Ltd.

Emergency Measures:

In case of hazardous waste leakage: Once an abnormality occurs, immediately report to the shift supervisor, who will immediately notify the relevant hazardous waste administrator and rush to the scene to carry out preliminary disposal work. If there are any injuries or poisoning, rescue the people first, provide first aid according to the situation, and seek medical attention immediately.

On-site rescue personnel must wear relevant protective equipment and strictly follow the instructions of the hazardous waste management system and regulations for on-site repair and rescue.

Duty Tel:0536-7868000 External rescue Tel: Fire alarm119 Emergency Tel:120

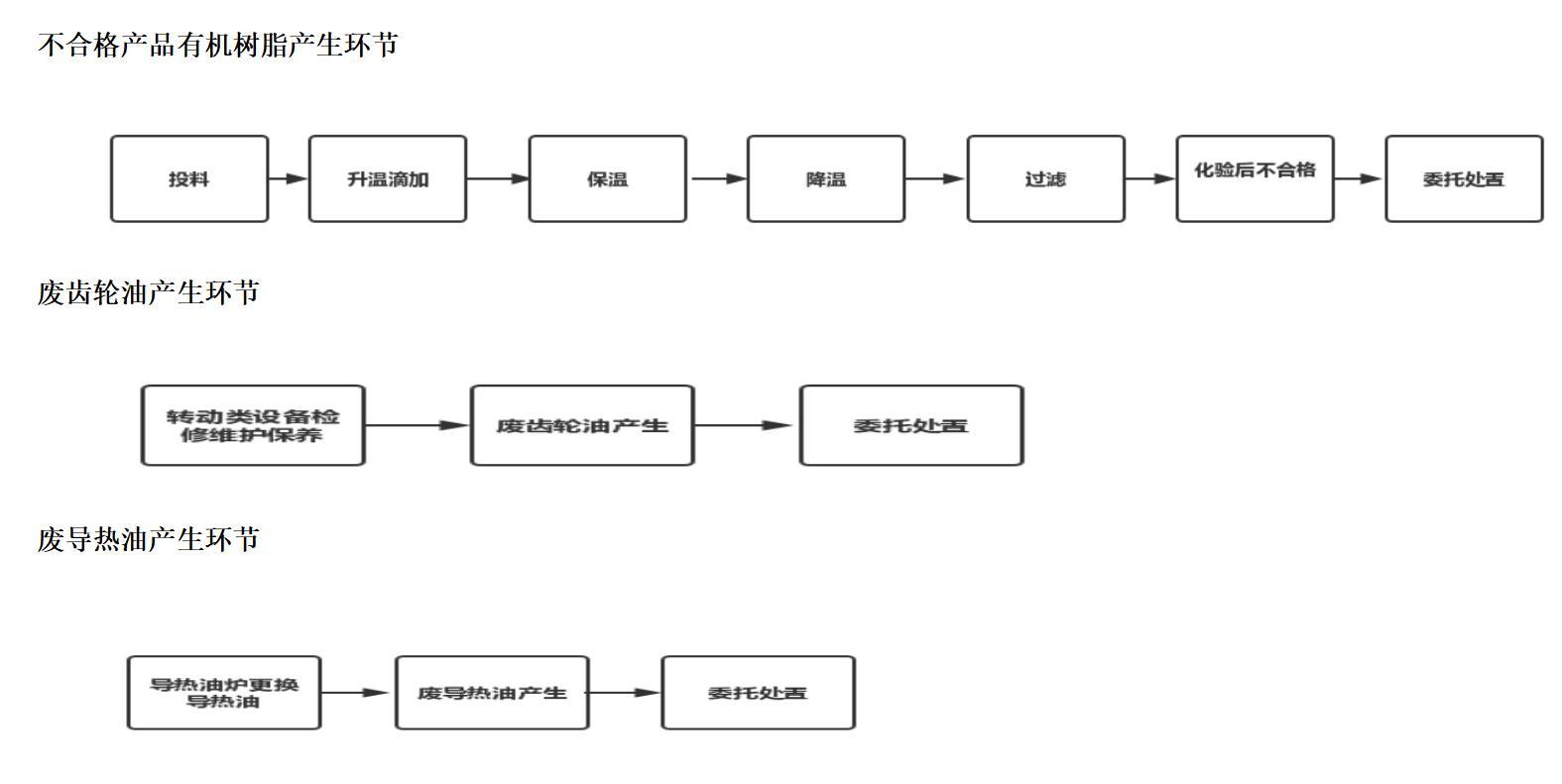

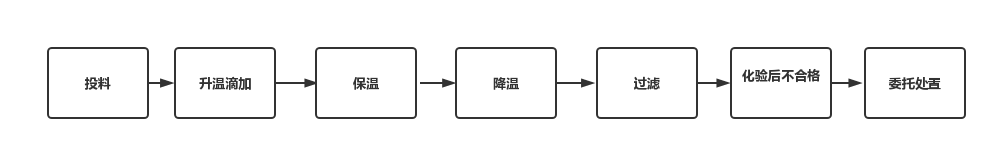

Non-conforming product organic resin generation process

Waste gear oil generation process

Waste heat transfer oil generation process

Waste cleaning solution generation process

Waste activated carbon generation process

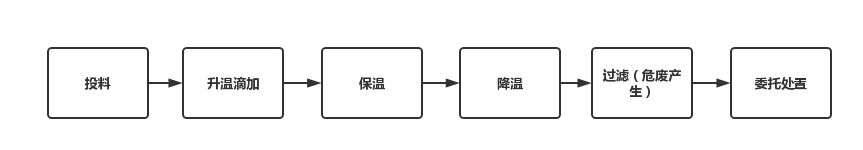

Organic resin waste generation process

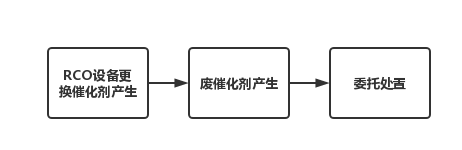

Waste catalyst generation process

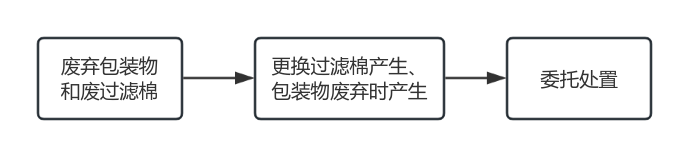

Waste filter cotton and waste packaging materials

Next

BLOGS

Over the past year, amidst challenges and difficulties, confidence has steadily grown. Cafule Company has achieved significant qualitative improvements and reasonable quantitative growth, demonstrating remarkable resilience and success. This is no small feat, given the challenging external environment. It reflects the leadership's astute response, comprehensive strategies, and the collective hard work and unity of the entire company. 2025 marks the final year of the 14th Five-Year Plan. Regardless of the negative impacts and pressures from the external environment, as long as we maintain our confidence and follow the leadership's strategic guidance, we will surely drive the company's economic benefits towards sustained and positive growth.

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

Focus on high-quality ecology and work together for sustainable development

Factory News: On May 11th, General Cui chaired a management meeting on environmental protection in the factory meeting room. Since the 18th National Congress of the Communist Party of China, the country has attached great importance to ecological civilization construction and ecological environmental protection, and incorporated it into the overall and strategic layout of "five in one" and "four comprehensives." Recently, relevant departments at all levels of the province, city, and district have introduced effective measures in energy conservation and emission reduction, ecological restoration and governance, and environmental risk prevention and control. As the governance work is carried out in depth, problems are gradually discovered and valued. It is against this backdrop that the company leaders, in response to the changing circumstances, actively coordinated and cooperated with the directly managed departments, and conducted a comprehensive investigation of the relevant facilities in the factory, and filled in the gaps in supporting materials. Strictly controlling environmental pollution and resource waste is taken as the primary task and implemented effectively to achieve "passing the standard for each item". After the meeting, General Cui led the persons in charge of the relevant management departments to conduct a careful inspection of the factory area, and put forward guiding opinions on matters to pay attention to in workshop production, equipment maintenance and repair, warehouse ventilation and odor removal, etc. The relevant matters that need to be improved within a time limit also have a schedule listed on the spot, striving to eliminate emerging problems in the bud.