Discussion on paint adhesion

Release time:

2019-08-13

The coating and substrate can be bonded together through mechanical bonding, physical adsorption, mutual diffusion, hydrogen bonding, and chemical bonding. The adhesion force generated by these interactions determines the adhesion between the paint film and the substrate. This adhesion should be the sum of various bonding forces between the paint film and the substrate. Below, we will analyze various bonding forces.

I. Adsorption Force Paint film and misidentification There are interatomic and intermolecular forces between the materials, including chemical bonds, hydrogen bonds, and van der Waals forces. If the distance between two ideal planes is10-9Then, the van der Waals force can be calculated to reach (9.8~98Mpa), the distance is (3~4)*10-10Then, it can reach (98~980Mpa). This value is far higher than the strength achievable by the best structural adhesives. However, it is difficult for two solids to have such an ideal situation. Even after polishing, the contact between two planes is difficult to reach 1% of the total area. As long as the coating can fully wet the substrate surface before curing, it should have good adhesion (like our company's productsCFU2050D,has excellent substrate wetting properties and has wide adhesion to many substrates). The actual adhesion of the paint film is far less than the calculated theoretical strength. If the substrate is inorganic, it is hydrophilic and has a layer of water film adsorbed from the environment. In this case, the hydrophobic groups in the coating are difficult to wet it, resulting in poor adhesion; when the substrate is organic, such as plastic substrates, such asPE、PPsubstrates, they do not have polar groups themselves, and the adhesion is poor; most importantly, this bonding is always defective, and the adhesion strength does not depend on the total molecular force but on the force of the weakest local part.

Two surfaces bonded only by van der Waals forces are essentially physical adsorption. This action is easily replaced by water vapor in the air. Therefore, to ensure strong bonding between the coating and the substrate, this physical adsorption alone is insufficient.

II. Mechanical Bonding The surface of any substrate cannot be smooth. Even if it looks smooth to the naked eye, it is very rough microscopically. Some surfaces, such as wood, paper, cement, and surfaces coated with primer, are porous. The coating can penetrate into these recesses or pores, and after curing, it is like many small hooks and wedges that bond the paint film and the substrate together.

III. Chemical Bond Bonding The strength of chemical bonds, including hydrogen bonds, is much stronger than van der Waals forces. Therefore, if hydrogen bonds or chemical bonds can be formed between the coating and the substrate, the adhesion will be much stronger. For example, when polymer molecules have hydroxyl, carboxyl, and amino groups, they are prone to hydrogen bonding with oxygen atoms or hydroxyl groups on the substrate surface, thus enhancing adhesion. Active groups on the polymer can also chemically react with metals. For example, phenolic resins can react chemically with aluminum, stainless steel, etc., at higher temperatures, and epoxy resins can also react chemically with the aluminum surface (like our company'sCFU1655Epoxy-modified hydroxyacrylic resin,CFP5050Epoxy-modified thermoplastic acrylic resin both have good adhesion to aluminum).

IV. Diffusion The film-forming substance in the coating is a polymer chain molecule. If the substrate is also a polymer material, then under certain conditions, due to the Brownian motion of molecules or segments, the molecules of the coating and the molecules in the misidentified material can mutually diffuse, which is essentially a process of mutual dissolution at the interface, leading to the disappearance of the interface. This requires both similar solubility parameters, and on the other hand, both must be above the glass transition temperature. Therefore, increasing the temperature is also a method to promote diffusion and improve adhesion (like our company'sCFP7250has good adhesion to plastic substrates, and has good alcohol resistance, silver powder orientation, and gloss, which is particularly advantageous in home appliances and toy paints).

V. Electrostatic Action When the coating and substrate come into contact, if the electron affinity is different, they can be electron donors and acceptors, forming a double electron layer and generating electrostatic force. For example, when a metal substrate is painted, the organic coating has a high electron affinity and easily obtains electrons from the metal substrate. In this way, a contact potential is generated at the interface, forming a double layer and generating electrostatic attraction, thus improving adhesion. (Like our company'sCFU2050Nis this type of resin, which has good adhesion to high-density fiberglass reinforced plastics, glass fibers, nylon fiberglass, and high-crystallinity metal layers; for substrates with higher crystallinity,PPproduced by our company,CFP5045AbecauseCFP5045Acontains special modifications in the chlorinated polypropylene, it can form a strong adhesion withPPsubstrate, so it has good adhesion and secondary adhesion after soaking in water).

In summary, to improve the adhesion of the coating to the substrate, on the one hand, the resin should be selected well, and on the other hand, the substrate treatment and baking conditions should be adjusted.

BLOGS

Over the past year, amidst challenges and difficulties, confidence has steadily grown. Cafule Company has achieved significant qualitative improvements and reasonable quantitative growth, demonstrating remarkable resilience and success. This is no small feat, given the challenging external environment. It reflects the leadership's astute response, comprehensive strategies, and the collective hard work and unity of the entire company. 2025 marks the final year of the 14th Five-Year Plan. Regardless of the negative impacts and pressures from the external environment, as long as we maintain our confidence and follow the leadership's strategic guidance, we will surely drive the company's economic benefits towards sustained and positive growth.

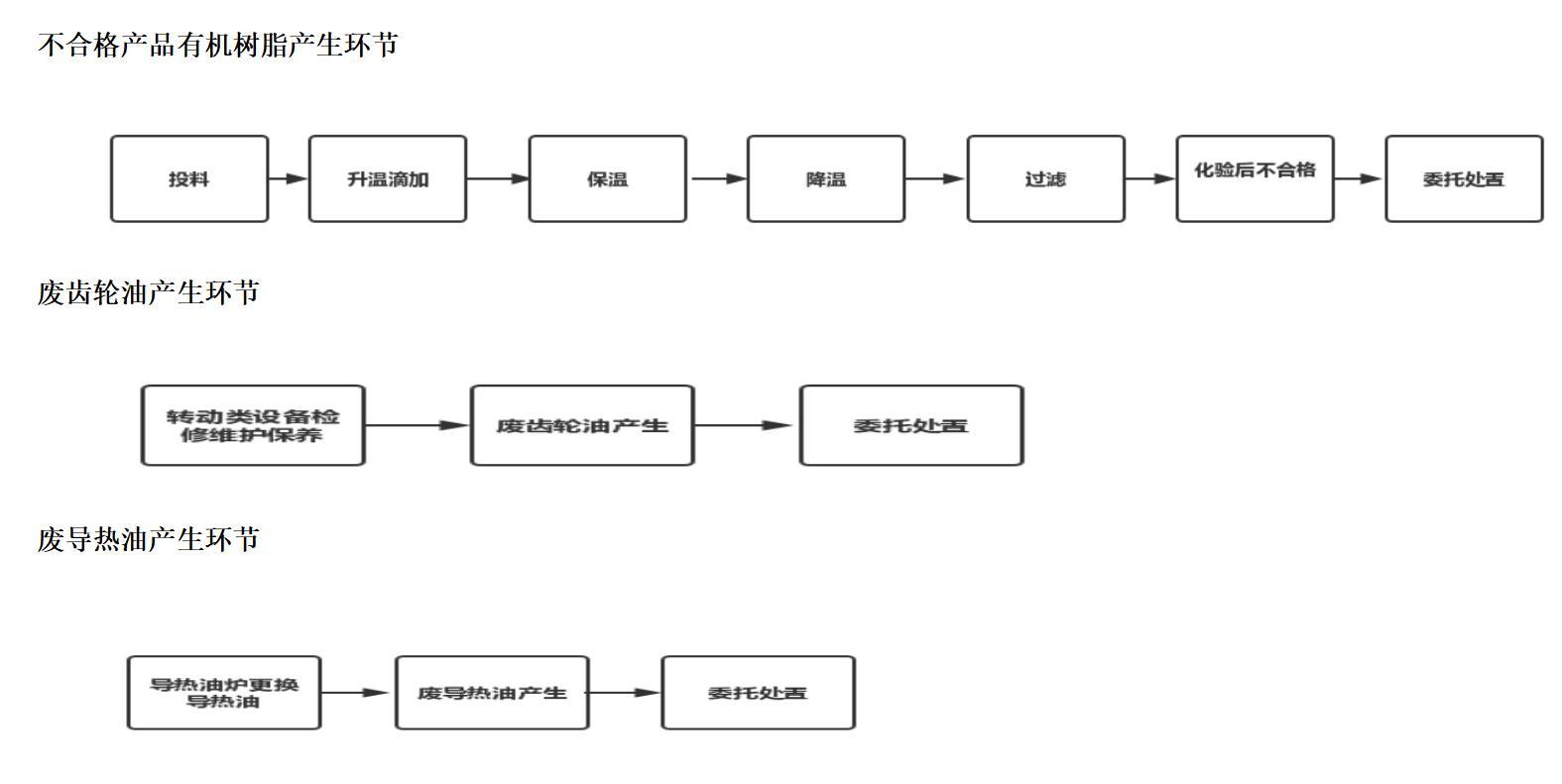

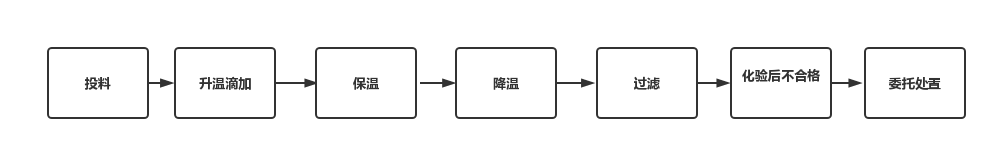

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

Focus on high-quality ecology and work together for sustainable development

Factory News: On May 11th, General Cui chaired a management meeting on environmental protection in the factory meeting room. Since the 18th National Congress of the Communist Party of China, the country has attached great importance to ecological civilization construction and ecological environmental protection, and incorporated it into the overall and strategic layout of "five in one" and "four comprehensives." Recently, relevant departments at all levels of the province, city, and district have introduced effective measures in energy conservation and emission reduction, ecological restoration and governance, and environmental risk prevention and control. As the governance work is carried out in depth, problems are gradually discovered and valued. It is against this backdrop that the company leaders, in response to the changing circumstances, actively coordinated and cooperated with the directly managed departments, and conducted a comprehensive investigation of the relevant facilities in the factory, and filled in the gaps in supporting materials. Strictly controlling environmental pollution and resource waste is taken as the primary task and implemented effectively to achieve "passing the standard for each item". After the meeting, General Cui led the persons in charge of the relevant management departments to conduct a careful inspection of the factory area, and put forward guiding opinions on matters to pay attention to in workshop production, equipment maintenance and repair, warehouse ventilation and odor removal, etc. The relevant matters that need to be improved within a time limit also have a schedule listed on the spot, striving to eliminate emerging problems in the bud.