The mixing ratio of amino resin and acrylic resin

Release time:

2019-08-13

Amino baked paint, due to its high crosslinking density, high solids and low viscosity, results in a coating with high fullness, high gloss, high hardness, good bright reflection, good oil resistance, good alkali resistance, good water resistance, and good wear resistance. Therefore, amino baked paint is widely used. Amino resin, as a crosslinking agent in amino baked paint, plays a crucial role in the proportion of amino baked paint coatings. So how should the content of amino resin in the coating formula be set? Let's discuss this below.

First, let's understand the types, composition, and characteristics of amino resins.

Amino resins, according to structural units, can be divided into(1)urea-formaldehyde resin,(2)melamine-formaldehyde resin,(3)benzoyl melamine-formaldehyde resin。Because the polarity of hydroxymethyl is very high, if etherification is not carried out, these three types of resins are difficult to dissolve in organic solvents, and their compatibility with acrylic resins, polyester resins, and alkyd resins is not good. Therefore, methanol or butanol is generally used for etherification to reduce polarity, so that it can be dissolved in organic solvents and have good compatibility with acrylic resins, polyester resins, and alkyd resins. According to the different degrees of etherification, it is divided intopartial etherification, high etherification and complete etherificationSeveral categories. The higher the degree of etherification, the lower the polarity. Among them, the main groups participating in the reaction of amino resins are imino, hydroxymethyl, and alkoxy. Among them, methylene and hydroxymethyl can be self-crosslinked, and hydroxymethyl, while self-crosslinking, is also the main reactive group with the main resin; alkoxy is hydrolyzed into hydroxymethyl in the presence of acid and then participates in the reaction.

Secondly, considering the reactive groups of the main resin and the amino resin.

Generally speaking, the hydroxyl, carboxyl, imino groups, etc. on the main resin (acrylic resin, polyester resin, alkyd resin, etc.) are used for crosslinking, but in many cases, these groups also provide the adhesion to the substrate. Therefore, after the amino resin crosslinks with the main resin, many polar groups are reacted away, which will affect the adhesion. Therefore, for amino resins, urea-formaldehyde resin is more suitable for use in primers, while melamine-formaldehyde resin and benzoyl melamine-formaldehyde resin are used in intermediate coats and topcoats. Therefore, in some coatings, an excess of amino resin or an excess of main resin should be selected to retain a certain amount of polar groups to maintain adhesion. This is something that needs to be prioritized in many cases.

Finally, considering the influence of the reactivity of the groups on the amino resin.

Generally speaking, under different reaction temperatures and different amounts of acid catalysts, the reaction mechanisms of various groups in amino resins are different. Sometimes they are more inclined to self-polymerization, and sometimes they are more inclined to crosslinking. In this case, the properties of the resulting coating will vary greatly. As a coatings engineer, one should have a deep understanding of the reactivity of amino resins, and be able to macroscopically control“the degree of self-crosslinking of amino resin and crosslinking with the main resin”、“the retention of polar groups on amino resin and the main resin”have an ideal evaluation, which can make the obtained coating achieve a perfect result. Just like improving the water resistance of the coating, on the one hand, a certain amount of active groups should be retained to generate strong chemical forces with the substrate, on the other hand, the active groups should be minimized to reduce the affinity with water. This is a very complex result.

In summary:

For example, for a thermosetting resin containing2.34%hydroxyl group percentage and acid value = <8mg/g,how should the amount of amino resin be selected?CFR8060经计算

经计算100g的CFR8060the molar amount of hydroxyl groups contained in0.08moland the molar amount of carboxyl groups0.014mol(can be ignored, only to improve the hydrolysis of alkoxy),if we choose only hexamethoxy melamine-formaldehyde resin, and considering that all six methoxy groups in hexamethoxy melamine-formaldehyde resin react with hydroxyl groups, then only0.08/6=0.013mol的HMMM,converted to mass is300*0.013=4g,in other words, it is said that we100g的CFR8060if all the hydroxyl groups contained in4g的HMMM,then the resulting coating is the best, but considering the size of the molecular weight, generally speaking,HMMMthe amount should be larger. LikeHMMM,we generally control the solid content ratio to7:1,instead of15:1,generally speaking, if it is an acrylic resin, because the molecular weight of the acrylic resin is larger, and the monomerHMMMthe molecular weight is smaller, so in order to fully react,HMMMthe amount should be significantly excessive, sometimes even taking the solid content of3:1This allows many methoxy groups to remain unreacted. For the amount of high imino resin used, it is similar to the amount of butoxy-functional amino resin used. Considering the self-crosslinking of imino and hydroxymethyl groups, the amount of amino resin is generally increased, usually controlled at a ratio of main resin: amino resin = (1.7:1~4:1). Based on the fact that higher temperatures are more prone to self-crosslinking, the amount of amino resin should be increased when the temperature is higher, generally kept at the upper limit of the ratio, so as to ensure the effectiveness of the crosslinking reaction. In addition, with more hydroxyl groups in the main resin, the proportion of amino resin should also be increased accordingly.

Lower temperature limit

Upper temperature limit

Acidic

Acid-free

Completely methylated amino resinHMMM

3:1~5:1

5:1~7:1

3:1~5:1

5:1~7:1

Partially methylated amino resin

2.5:1~4:1

2.5:1~4:1

2.5:1~5:1

2.5:1~5:1

High imino, high etherified amino resin

1.5~3:1

1.5~3:1

1.5~3:1

1.5~3:1

Mixed etherified amino resin

2:1~4:1

2:1~4:1

2:1~4:1

2:1~4:1

Butoxy-functional amino resin

1.7:1~4:1

1.7:1~4:1

1.7:1~4:1

1.7:1~4:1

Methylated urea-formaldehyde resin

1.7:1~4:1

1.7:1~4:1

1.7:1~4:1

1.7:1~4:1

Of course, the activity of the groups on the main resin will also affect the amount of amino resin used, so the proportions in the table above are only a theoretical summary. The specific amount needs to be considered based on the specific experimental situation.

BLOGS

Over the past year, amidst challenges and difficulties, confidence has steadily grown. Cafule Company has achieved significant qualitative improvements and reasonable quantitative growth, demonstrating remarkable resilience and success. This is no small feat, given the challenging external environment. It reflects the leadership's astute response, comprehensive strategies, and the collective hard work and unity of the entire company. 2025 marks the final year of the 14th Five-Year Plan. Regardless of the negative impacts and pressures from the external environment, as long as we maintain our confidence and follow the leadership's strategic guidance, we will surely drive the company's economic benefits towards sustained and positive growth.

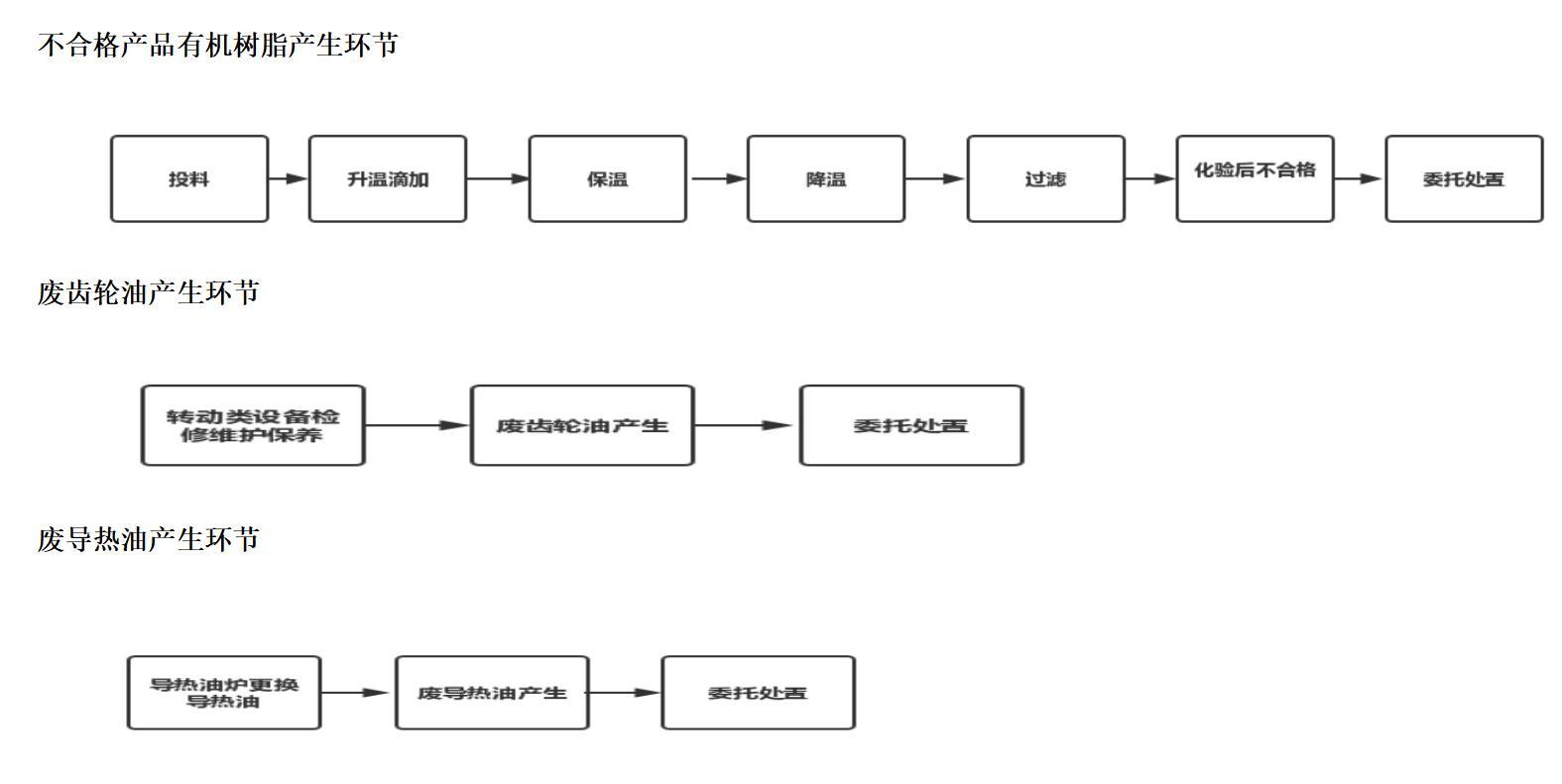

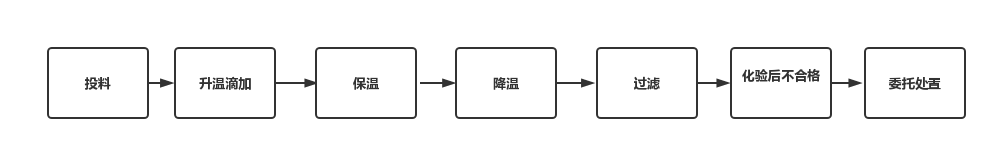

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

Focus on high-quality ecology and work together for sustainable development

Factory News: On May 11th, General Cui chaired a management meeting on environmental protection in the factory meeting room. Since the 18th National Congress of the Communist Party of China, the country has attached great importance to ecological civilization construction and ecological environmental protection, and incorporated it into the overall and strategic layout of "five in one" and "four comprehensives." Recently, relevant departments at all levels of the province, city, and district have introduced effective measures in energy conservation and emission reduction, ecological restoration and governance, and environmental risk prevention and control. As the governance work is carried out in depth, problems are gradually discovered and valued. It is against this backdrop that the company leaders, in response to the changing circumstances, actively coordinated and cooperated with the directly managed departments, and conducted a comprehensive investigation of the relevant facilities in the factory, and filled in the gaps in supporting materials. Strictly controlling environmental pollution and resource waste is taken as the primary task and implemented effectively to achieve "passing the standard for each item". After the meeting, General Cui led the persons in charge of the relevant management departments to conduct a careful inspection of the factory area, and put forward guiding opinions on matters to pay attention to in workshop production, equipment maintenance and repair, warehouse ventilation and odor removal, etc. The relevant matters that need to be improved within a time limit also have a schedule listed on the spot, striving to eliminate emerging problems in the bud.