Factors Affecting the Fullness of Coating Resins---CFU2970A

Release time:

2019-08-13

When designing paint formulations, paint engineers desire high-gloss, high-fullness, and high-brightness coatings. However, this is often not achieved. Why is that?

The factors affecting gloss and brightness in coatings include: the wettability of resin and pigment, the compatibility of various components in the coating, the smoothness and roughness of the coating, the smoothness, fullness, and the amount of reflected and transmitted light from the coating surface. What determines fullness, and how is it described?

Although the gloss, brightness, and fullness of the coating are comprehensively affected by various components in the coating, the resin plays a key role, especially fullness, which is more closely related to the resin. Fullness generally refers to the degree of compactness of the coating observed macroscopically after film formation; in other words, the coating has minimal texture, and the surface feels smooth and round. What kind of resin produces this feeling? We know that a coating generally consists of resin, solvent, pigments (in colored paints), and auxiliaries. The solvent eventually escapes from the gaps between the resin molecules. The fewer and smaller the gaps between the resin molecules, the higher the fullness and smoothness of the coating. When pigments are present, the closer the distance between the resin and the pigment, the higher the fullness of the final coating.

Generally, resin manufacturers try to achieve this effect in three ways: First, they employ various methods to produce high-solid low-viscosity resins, thinking this solves everything, but they are unaware of the potential hazards involved. Second, increase polar groups and ensure uniform distribution of polar groups in the resin. For the first method, the size of the molecule is generally an indicator of viscosity. Low viscosity generally indicates low molecular weight. Low molecular weight often leads to a significant reduction in chemical resistance, weather resistance, and water resistance. Achieving unchanged performance is quite difficult. For the second method, it is a test of the process and cost. In today's competitive resin manufacturing industry, few manufacturers dare to do this. In view of this situation, our company has developed and produced a resin with excellent fullness and a relatively low price.CFU2970A,CFU2970AIt is a resin with excellent pigment wettability, high fullness, and excellent weather resistance.QUV313Aging1000hours, gloss loss is only10%)

For detailed performance of CFU2970A, please refer to the product Description for CFU2970A

BLOGS

Over the past year, amidst challenges and difficulties, confidence has steadily grown. Cafule Company has achieved significant qualitative improvements and reasonable quantitative growth, demonstrating remarkable resilience and success. This is no small feat, given the challenging external environment. It reflects the leadership's astute response, comprehensive strategies, and the collective hard work and unity of the entire company. 2025 marks the final year of the 14th Five-Year Plan. Regardless of the negative impacts and pressures from the external environment, as long as we maintain our confidence and follow the leadership's strategic guidance, we will surely drive the company's economic benefits towards sustained and positive growth.

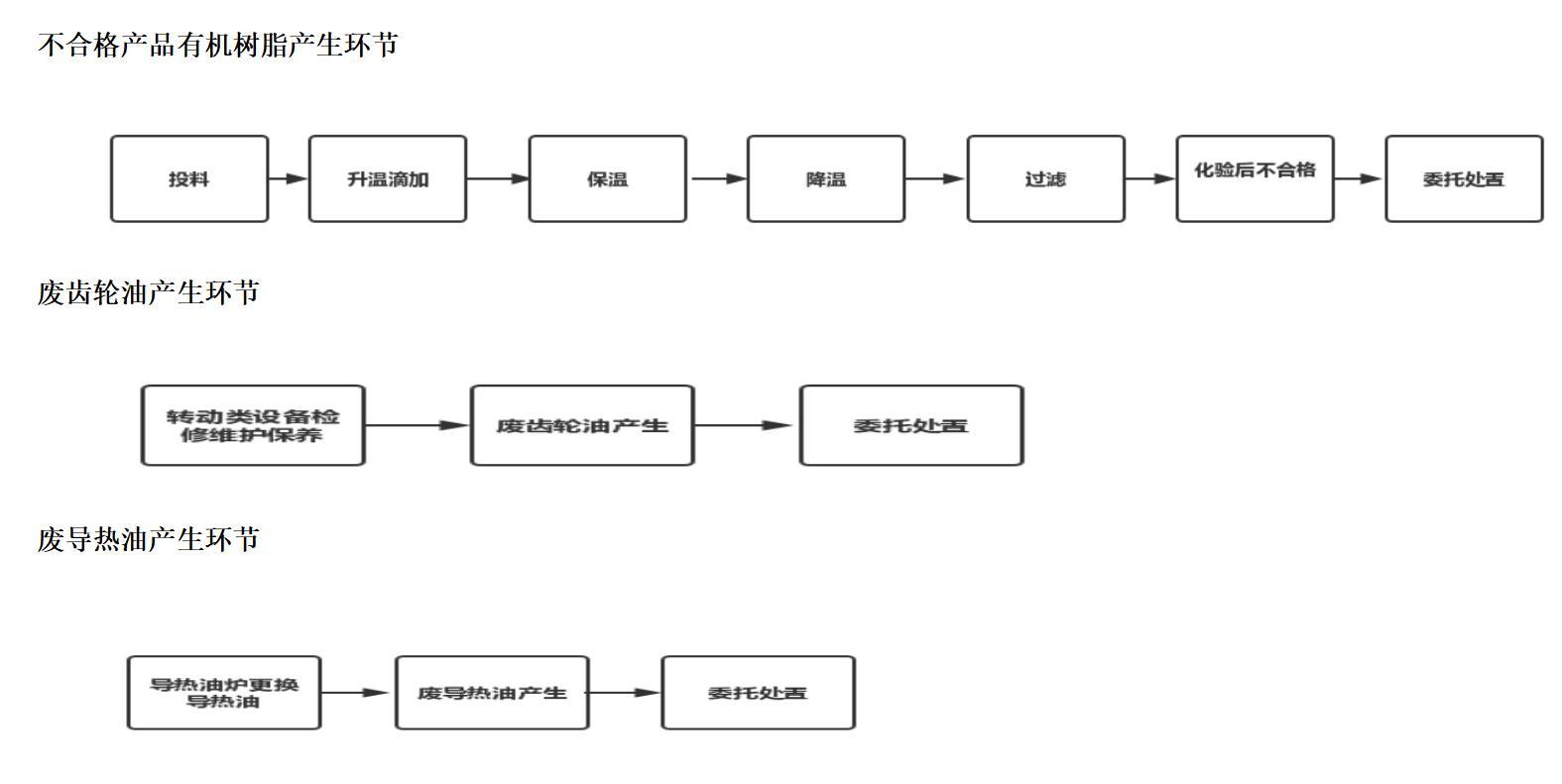

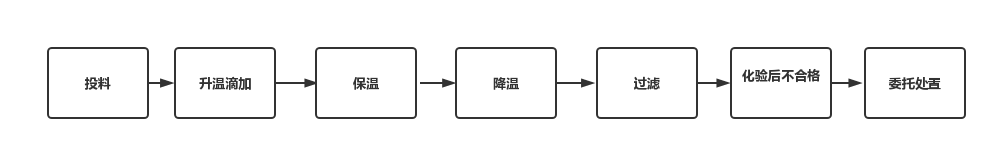

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

To implement national requirements on hazardous waste management, strictly control and manage the company's hazardous waste, prevent environmental pollution accidents, and ensure sustainable production, this system is specially formulated.

Focus on high-quality ecology and work together for sustainable development

Factory News: On May 11th, General Cui chaired a management meeting on environmental protection in the factory meeting room. Since the 18th National Congress of the Communist Party of China, the country has attached great importance to ecological civilization construction and ecological environmental protection, and incorporated it into the overall and strategic layout of "five in one" and "four comprehensives." Recently, relevant departments at all levels of the province, city, and district have introduced effective measures in energy conservation and emission reduction, ecological restoration and governance, and environmental risk prevention and control. As the governance work is carried out in depth, problems are gradually discovered and valued. It is against this backdrop that the company leaders, in response to the changing circumstances, actively coordinated and cooperated with the directly managed departments, and conducted a comprehensive investigation of the relevant facilities in the factory, and filled in the gaps in supporting materials. Strictly controlling environmental pollution and resource waste is taken as the primary task and implemented effectively to achieve "passing the standard for each item". After the meeting, General Cui led the persons in charge of the relevant management departments to conduct a careful inspection of the factory area, and put forward guiding opinions on matters to pay attention to in workshop production, equipment maintenance and repair, warehouse ventilation and odor removal, etc. The relevant matters that need to be improved within a time limit also have a schedule listed on the spot, striving to eliminate emerging problems in the bud.